| PROJECT: | CRS Industrial Water – Barrow Island Sewage Treatment Plant |

|---|---|

| CUSTOMER: | CRS Industrial Water |

| DESCRIPTION: | CRS Industrial Water Treatment Systems is an Australian-owned engineering company specialising in the field of water and wastewater treatment. |

| REQUIREMENTS: | KAPP Engineering was contracted by CRS to design and develop the PLC control system for the Barrow Island Sewage Treatment Plant as part of the multi-billion dollar Gorgon Project.

The overall process comprises of the following sub-processes:

|

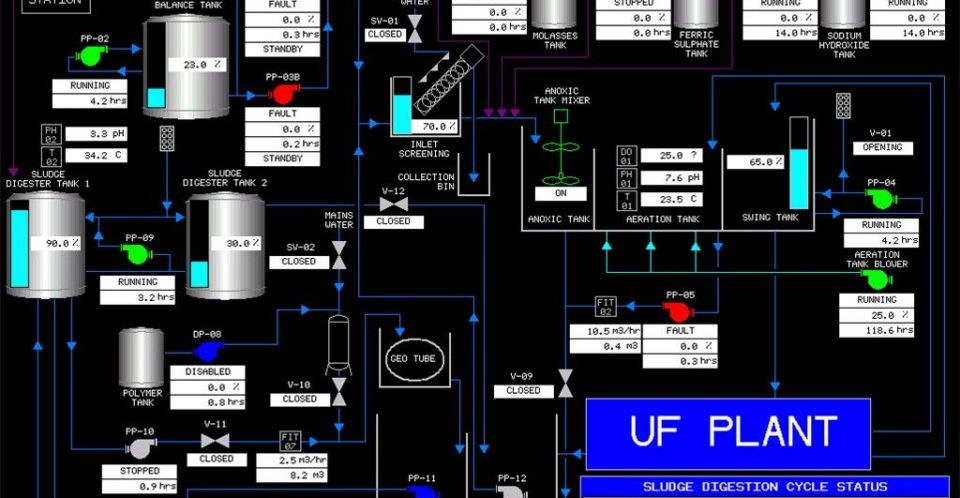

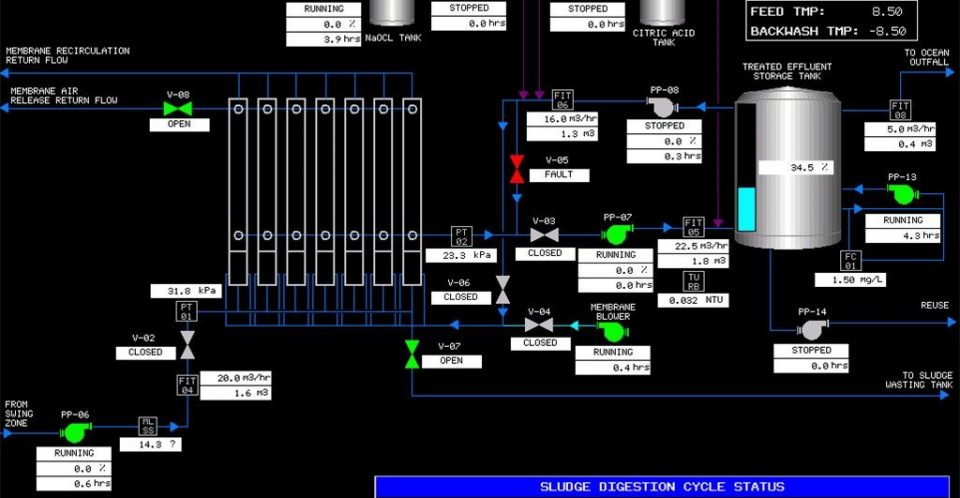

| SOLUTION: | The control system comprised of a Modicon M340 PLC, which included 128 digital I/O and 36 analogue I/O. A Magelis 15” colour touch screen provided the operator interface, while an Ethernet communications network allowed for the monitoring and control of 8 x ABB variable speed drives (VSDs).

KAPP Engineering designed and developed a flexible and user-friendly control system, including P&ID style graphic screens which allow the operator to view the status of the entire plant at a glance. Intuitive system settings and maintenance mode controls ensure that the system is highly flexible and simple to maintain and troubleshoot. The final product was a fully-automated control system which included control and monitoring of the following equipment:

|

Gallery: