| PROJECT: | DFC Ceramics Australia – Dryer and 4 Head PLC Replacement |

|---|---|

| CUSTOMER: | DFC Ceramics Australia |

| DESCRIPTION: | DFC Ceramics manufactures Fire Assay Crucibles and Magnesite Cupels which are the first choice of most major laboratories both within Australia and around the world. |

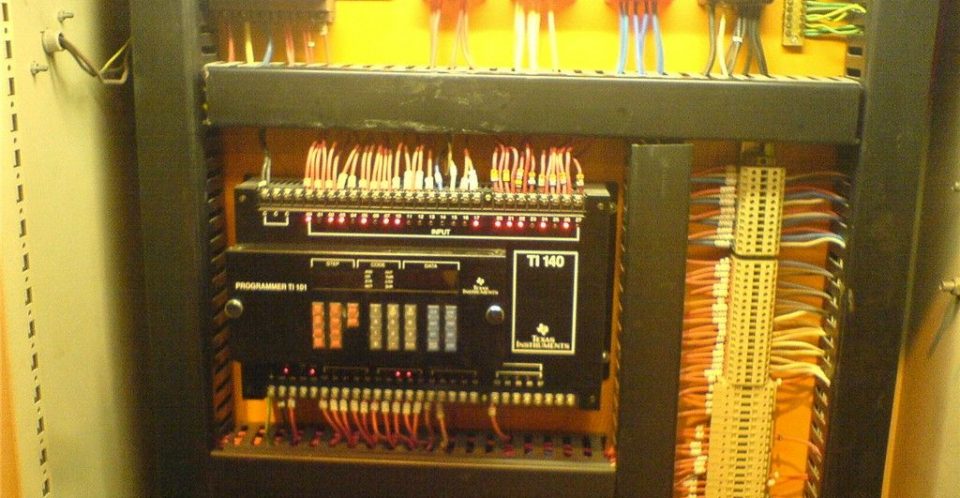

| REQUIREMENTS: | Following the successful replacement of a TI505 PLC Control System for DFC Ceramic’s Kiln with a new Koyo PLC Control System, DFC Ceramics decided to replace two other old TI Control Systems in their Malaga based plant during their 2006 Christmas shutdown period to prevent any loss in production time. The first system to be replaced was a TI140 PLC System controlling a Dryer, and the second system was a TI505 PLC System controlling a 4 Head Machine. |

| SOLUTION: | KAPP Engineering was instructed to replace both systems with new Koyo PLC hardware to perform the exact same functionality as the old TI systems. For the 4 Head system the old TI505 PLC was replaced with a new Koyo DL205 PLC which consisted of the following:

KAPP Engineering added value to the system with the addition of a C-More Micro Touch Screen that enabled DFC operators to easily change specific attributes of the machine. The C-More Micro plugs directly into the Koyo PLC’s communications port (through which it communicates and receives power) for easy plug-in and removal. For the Dryer system the old TI140 PLC was replaced with a new Koyo DL205 PLC which consisted of the following:

In the case of both systems KAPP Engineering supplied complete replacement hardware for the old TI systems, updated all electrical drawings, and converted all original PLC code to the new Koyo PLC systems. Both systems were successfully upgraded during DFC Ceramic’s shutdown period such that no production time was lost. |

Gallery: